Zhejiang Jhenten Machinery Co.,Ltd.

Name:Henson.Zeng

Phone:+86 15957782988

Tel:+86 577-86867777

Email:info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

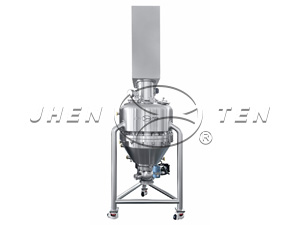

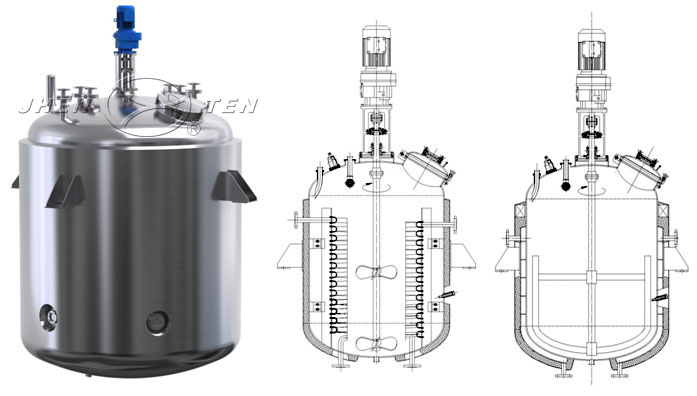

Reactor

Reactor

JTRFY reactor be designed, manufactured and inspected in accordance with the pressure vessel standard(GB150-2011) and the steel welded atmospheric pressure vessel standard(NB/T 47003.1-2009) , strictly meet to GMP certificate requirements.

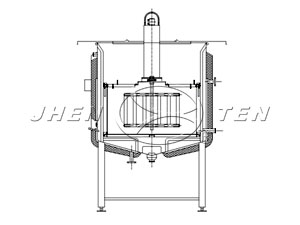

Inside Pipe coil Reactor Full Jacketed Reactor

(Three blade propeller agitator) (Anchor frame agitator)

JTRFY reactor be designed, manufactured and inspected in accordance with the pressure vessel standard(GB150-2011) and the steel welded atmospheric pressure vessel standard(NB/T 47003.1-2009) , strictly meet to GMP certificate requirements.

Jhenten reactor using vertical circular tanks, jacket can be made into a dimple jacket, coil jacket or the whole jacket, can heating or cooling, made of 316L or 304 stainless steel ,inside surface electrolytic mirror polishing or mechanical polishing, the outer surface adopts 304,all welded surface mirror or inferior smooth processing; Tanks welds adopt flanging process arc transition, smooth and easy to clean no dead corner, beautiful appearance.

Tank Optional Configuration

Reactor can configure aseptic air filter, thermometer(Digital display or Dial type), PH meter, pressure gauge, steam sterilization hole, sight glasses, sanitary manhole, liquid in-outlet, CIP cleaning ball, liquidometer and Liquid level control system(Bearing module, non-contact ultrasonic, static pressure transmitting device) and so on, also can configure as customers’ requirement.

Application

? Apply to petrochemical, fine chemistry, rubber industry, pesticide, dye, bio-pharmaceuticals and beverage, to complete the vulcanization, hydrogenation, alkylation, polymerization, condensation process.

Feature

? Reacor made of 316L or 304 has excellent mechanical properties, can bear high pressure, also can withstand the impact of the massive solid materials when feeding;With rapid heating, high temperature resistant, corrosion resistance, no rust, health, no pollution, etc.

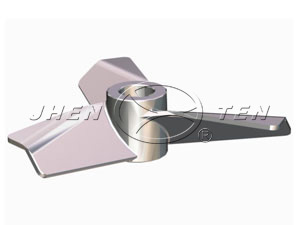

? Agitator with anchor type, frame type, impeller or turbine;using cycloidal reducer, gear reducer, and frequency control;Mechanical seal sealing device can use health level;Can use jacket, half pipe coil, cooling/heating coil structure, heating mode with steam, electric heating, heat conduction oil;Can be arbitrarily selected according to the user's technique.

? Reactor has 600L and 20000L, and other specifications, according to the actual requirment of customers.

Design Parameter

DesignPressure | (-0.1MPa~1.6MPa) |

Design | According tocustomers’requirement(0℃~160℃) |

Material

| Liner | 304、316L |

| Jacket | 304 |

| Insulation | Rockwool or PU |

| Feet | 304 |

Connection

In-outlet | Tri-clamp, Flange |

Surface finish

FinishType | Mechanicalpolishing, electrolytic polishing, sand blasting, pickling |

Polishingprecision |

Inner surface Ra≤0.4μm,, |

Normal Model And MainTechnical Parameters

| Parameters | Model | JTRFY—600 | JTRFY—1000 | JTRFY—2000 | JTRFY—3000 | JTRFY—4000 | JTRFY—5000 | |

| Effectivevolume:L | 600 | 1000 | 2000 | 3000 | 4000 | 5000 | ||

Barrel | Diameter:mm | Φ900 | Φ1100 | Φ1300 | Φ1600 | Φ1700 | Φ1800 | |

| Height:mm | 900 | 1000 | 1500 | 1500 | 1800 | 1800 | ||

Agitator | Power:kW | 1.1 | 1.5 | 2.2 | 2.2 | 3 | 4 | |

| RPM:r/min | 200(Push type)or60(Anchor frame)(The design canbe adjusted according to customer use condition) | |||||||

| JTRFY—6000 | JTRFY—8000 | JTRFY—10000 | JTRFY—12000 | JTRFY—15000 | JTRFY—20000 |

| 6000 | 8000 | 10000 | 12000 | 15000 | 20000 |

| Φ1900 | Φ2000 | Φ2200 | Φ2400 | Φ2600 | Φ2800 |

| 2000 | 2200 | 2400 | 2500 | 2700 | 3000 |

| 4 | 5.5 | 7.5 | 7.5 | 11 | 11 |

| 200(Push type)or60(Anchor frame)(The design canbe adjusted according to customer use condition) | |||||

| The above-mentioned data is the standard, for reference only.It can customizeaccording to customer's requirements. | |||||

Welcome to send an online inquiry! If you have any suggestions or questions about our products, you can Email us.info@jhenten.com, also feedback through this inquiry; we will reply to you within 24 hours. (Monday to Friday, 9:00-17:30)

Other Products

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.