Zhejiang Jhenten Machinery Co.,Ltd.

Name:Henson.Zeng

Phone:+86 15957782988

Tel:+86 577-86867777

Email:info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

Process System Skid

Intelligent vacuum emulsification system

The vacuum emulsification equipment can achieve high efficiency of mixing and dispersing by heating / cooling the material and optimizing the feeding mode of powder to avoid caking.

●Solid liquid enters the dispersion cavity directly to achieve more efficient dispersion and more smooth particle.

●The powder is easy to wet and distribute evenly and will not float in the container

●Processing high viscosity materials is one of biggest Advantages

Rapid homogenization

Our high vacuum emulsification system with integration design concept and complete system combination suits various production sites and brings more friendly man-machine interactive experience. We keep the value of preciseness in the whole production process and production control and select core components of the international high-quality brand to ensure the stability and reliability of the product The whole system meets global sanitary standard and the GMPC specification.

Our high vacuum emulsification system with integration design concept and complete system combination suits various production sites and brings more friendly man-machine interactive experience. We keep the value of preciseness in the whole production process and production control and select core components of the international high-quality brand to ensure the stability and reliability of the product The whole system meets global sanitary standard and the GMPC specification.

The vacuum emulsification equipment can achieve high efficiency of mixing and dispersing by heating / cooling the material and optimizing the feeding mode of powder to avoid caking.

●Solid liquid enters the dispersion cavity directly to achieve more efficient dispersion and more smooth particle.

●The powder is easy to wet and distribute evenly and will not float in the container

●Processing high viscosity materials is one of biggest Advantages

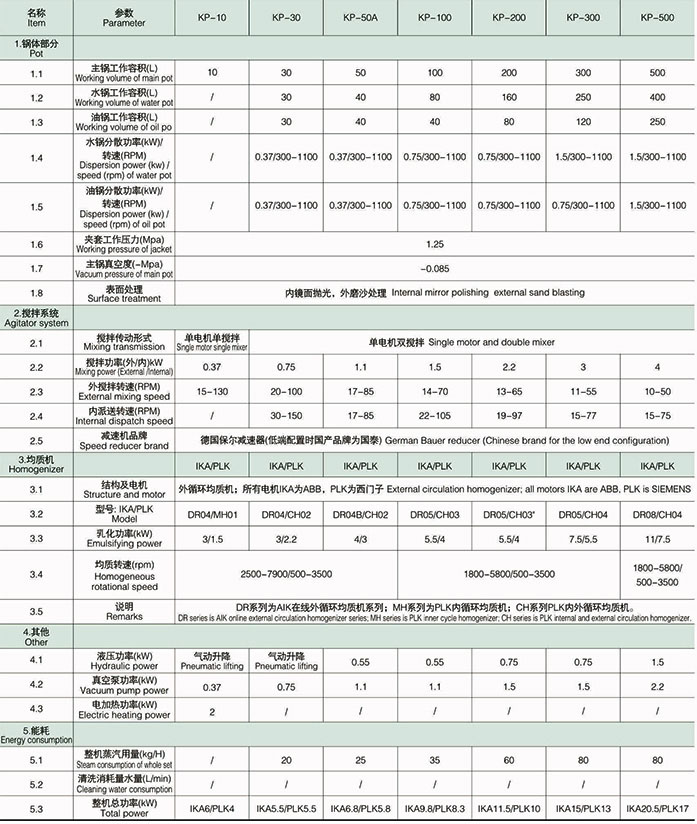

To reach different result you can choose our emulsification equipment or IKA emulsification equipment according to the technical requirements.

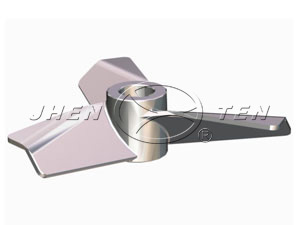

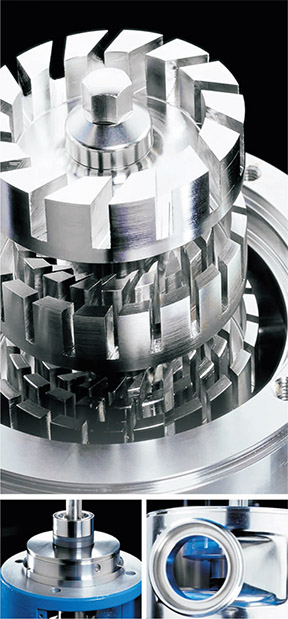

Two agitators for choice

The lift vacuum emulsifier provides 2 kinds of agitators for you to choose. Revolving agitator is used for fine mixing of materials. By the vertical-horizontal mixing way the mixing process gets more thoroughly. The inner stirring agitator is hollow inside and it can be heated or cooled, which greatly reduces the heating and cooling time. The emulsifying speed is 0-3500 rpm.

The lift vacuum emulsifier provides 2 kinds of agitators for you to choose. Revolving agitator is used for fine mixing of materials. By the vertical-horizontal mixing way the mixing process gets more thoroughly. The inner stirring agitator is hollow inside and it can be heated or cooled, which greatly reduces the heating and cooling time. The emulsifying speed is 0-3500 rpm.

The spiral impeller can be heated / cooled thoroughly reducing 40% time, thus greatly enhancing the stability of the emulsion and preventing the denaturation.

The spiral impeller can be heated / cooled thoroughly reducing 40% time, thus greatly enhancing the stability of the emulsion and preventing the denaturation.

Sanitary agitation design, a stirred impeller without screw installation

Sanitary agitation design, a stirred impeller without screw installation

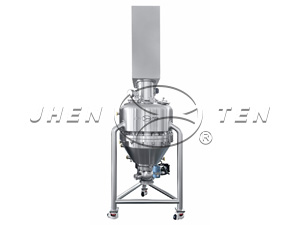

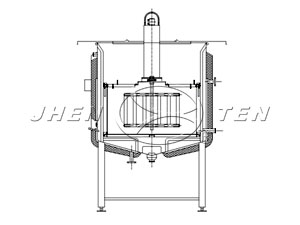

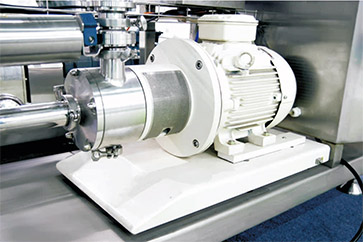

The lift type external circulation vacuum emulsifier is designed by Jhenten company specially for the products of high viscosity and emulsification for cosmetics and pharmaceutical industries.

The lift type external circulation vacuum emulsifier is designed by Jhenten company specially for the products of high viscosity and emulsification for cosmetics and pharmaceutical industries.

Features

1,、the material can be emulsified in continuous circulation.

2、the material of high viscosity can be dealt with more thoroughly.

3、The external circulation emulsifier can replace the feed pump and can be recycling cleaned.

The mixing is used by positive and reverse double scraping edge and it is designed with high speed external circulation emulsification head.

Cleaning system

Lifting type vacuum emulsifier

Lock protection device, the higher safety, stable quality applied from labs to large mass production.

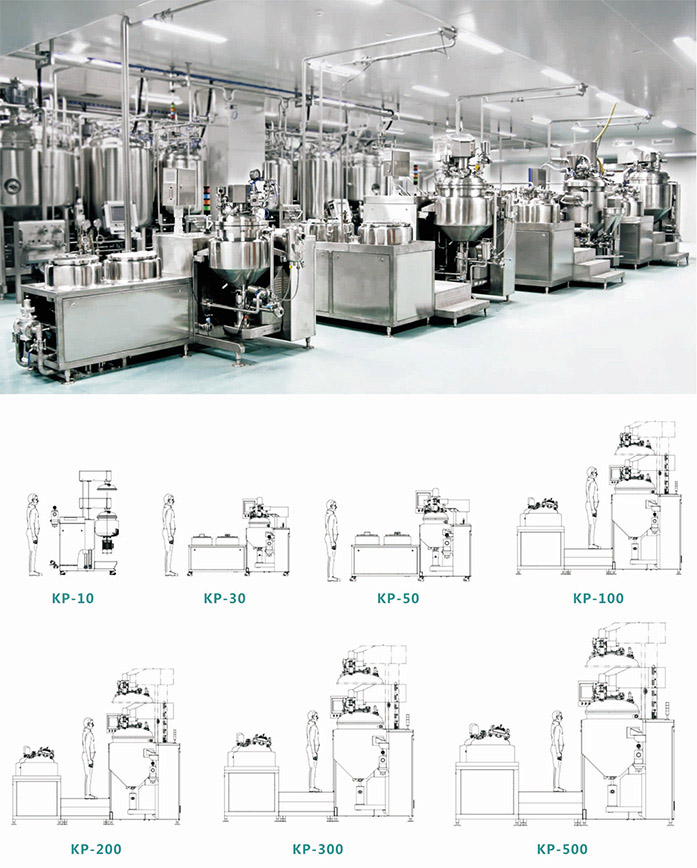

Our innovative lifting vacuum emulsification system, from experimental KP-10, pilot KP-30 to production KP-50, allows you to develop and produce products and optimize the production process.

The same design, the geometric characteristics of the working head and operation parameters can continue to use without adjusting the settings, only need to adjust the system according to the output.

Experimental type KP-10

Production type KP-10

Characteristic

●With oil pressure lifting system, can lift the lid freely.

●The mixing system adopts double edge mixing and frequency conversion speed regulation, which can meet the production of different process requirements.

●Advanced homogenizer, unique structure, reliable sealing (mechanical seal is German Bergman), the emulsification speed is 0-3500 turn / min(Korea LG variable frequency governor)

●The material is imported SUS304 or SUS316L stainless steel. The tank and pipe are mirror polished in accordance with the GMP specification.

●The vacuum deaeration can achieve the aseptic requirements, and vacuum suction avoid the flying powder.

●According to the requirements of the process, the tank can be heated or cooled on the way of steam or electric heating according to the requirements of the customer.

Welcome to send an online inquiry! If you have any suggestions or questions about our products, you can Email us.info@jhenten.com, also feedback through this inquiry; we will reply to you within 24 hours. (Monday to Friday, 9:00-17:30)

Other Products

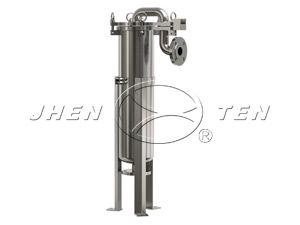

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.